Zoom

Making a rope

Making a rope involves several steps:

1. The choice of raw materials

The choice of raw materials is essential: these will be checked and tested to verify the correspondence of the desired characteristics.

Internally, we talk about “wisp” but for more understanding the term “threads” is more appropriate. The origin of raw materials is different for different materials. It all depends on quality, price and other parameters.

2. Assembly

The next process is the creation of a stream of parallel threads called the assembly.

At this stage there is no twisting or braiding.

3. Twisting

Then comes the stage of twisting, which consists in giving a twist to the wisp (thread) to give it mechanical values. Twisting consists of twisting the thread in 2 directions: in “S” when twisted to the right; in “Z” on the left.

Then you get a twist.

4. Wiring

The wiring phase is not automatic. It depends on the ropes.

Wiring consists of applying a twist in the opposite direction to the 1st twist.

5. Dubbing

Once the twisting and wiring is completed, the dubbing takes place.

At dubbing, the coils of the raw materials which have been assembled, twisted and for some cabled, are filled.

6. Braiding

The operation of the braiding consists in braiding the product whether in core or sheath.

To these steps are added quality tests, finishing and packaging (winding, labelling).

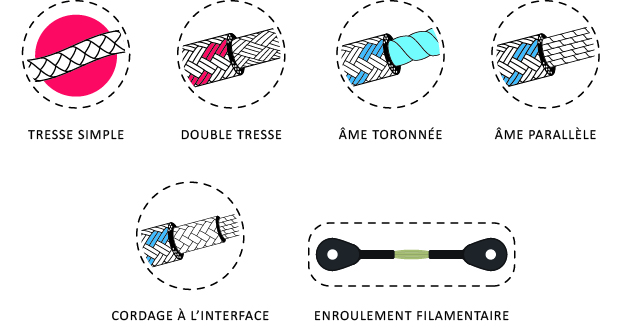

Types of rope construction

Our know-how allows us to make different types of ropes, from a simple construction to the most complex constructions. Our main types of construction are: